Workshop Venue: AUTODESK BUILD Space

Adress: 23 Drydock Ave, Boston, MA 02210

Workshop Schedule

Monday, October 30 2017

Workshops Day 01 (Autodesk BUILD Space)

| 08:30 am - 12:00 pm Workshops Introduction |

| 12:00 pm - 01:00 pm Lunch |

| 01:00 pm - 05:00 pm Workshop Sessions |

Tuesday, October 31 2017

Workshops Day 02 (Autodesk BUILD Space)

| 08:30 am - 12:00 pm Workshop Sessions |

| 12:00 pm - 01:00 pm Lunch |

| 01:00 pm - 05:00 pm Workshop Sessions |

Wednesday, November 1 2017

Workshops Day 03 (Autodesk BUILD Space)

| 08:30 am - 12:00 pm Workshop Sessions |

| 12:00 pm - 01:00 pm Lunch |

| 01:00 pm - 05:00 pm Workshop Sessions |

| 06:00 pm - 08:30 pm Workshops Closing Reception (RSVP only) |

Workshops

WORKSHOP 01

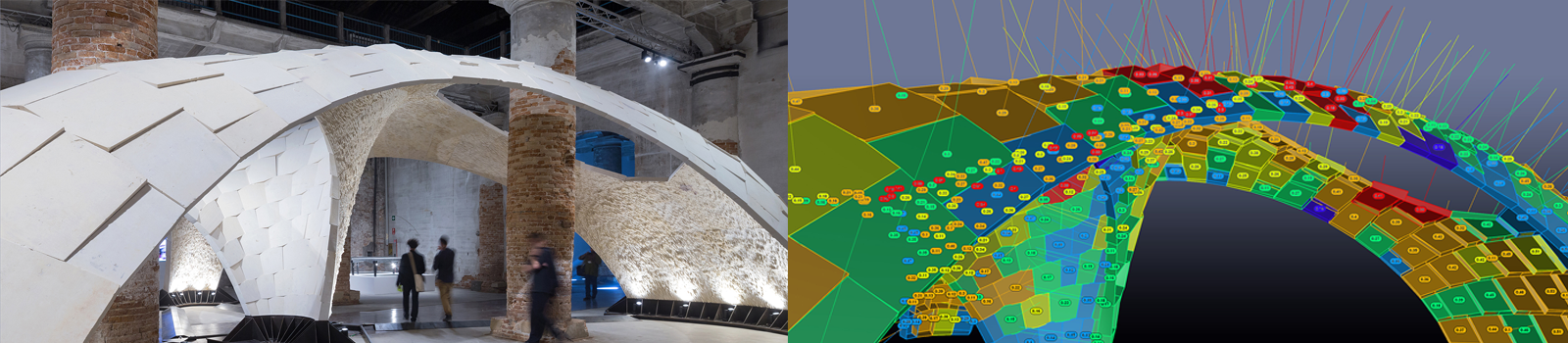

Computational Research in Architecture and Structures

Workshop Leaders:

Philippe Block (Block Research Group, ETH Zurich)

Tom Van Mele (Block Research Group, ETH Zurich)

Matthias Rippmann (Block Research Group, ETH Zurich)

Mariana Popescu (Block Research Group, ETH Zurich)

During this workshop participants learn how to address advanced research questions in architecture, structures, and digital fabrication through computation. On the first day, we will set up a development environment for scientific programming that will be used throughout the workshop, followed by a “scientific Python 101” and an introduction to compas, an open source, Python-based framework for “computational research in architecture and structures”. The introduction covers the key concepts of the compas framework and a series of representative code examples. The second day, is a step-by-step breakdown of the computational aspects of one of the recent core projects of the Block Research Group. The final day is a hackathon during which the participants have the chance to explore computational solutions to their own research problems with the help of the workshop tutors.

Machine / Hardware / Materials:- Internet access

- Code editor (i.e. Sublime Text)

- Scientific Python distribution (i.e. Anaconda)

- CAD software (i.e. Rhino, Maya, Blender)

- Basic scripting skills (preferably in Python)

- Their computer

WORKSHOP 02

Impossible Objects

Workshop Leaders:

Ana Herruzo (Herruzo-Pierce)

Brandon Kruysman (Kruysman | Proto)

Jonathan Proto (Kruysman | Proto)

Beyond the 2-Dimensional screen of graphics, and the three-dimensional aspect of products, designers are facing new challenges in light of advancement in artificial intelligence, robotics, and smart environments. In addition to common topics studied during the traditional design process (aesthetics, function, usability), robotic systems demand a closer investigation into the object in both time and space. This workshop aims to explore the often convoluted dialogue between our digital design environments and the physical realities we strive to realize them within. Our work will focus on bi-directional modes of communication between these environments in order to find new mediums of design opportunity.

Machine / Hardware / Materials:- Multimedia Equipment (i.e. 1080HD projectors)

- External motion tracking device (i.e. Kinect, HTC Vive)

- Optional: Motion Control System (i.e. low payload robot arm)

- Rhinoceros 5.0 / Grasshopper

- Derivative TouchDesigner

- Basic 3d modeling (preferred experience in parametric and animation software)

- Windows Laptop with Rhino/Grasshopper and TouchDesigner installed and activated

WORKSHOP 03

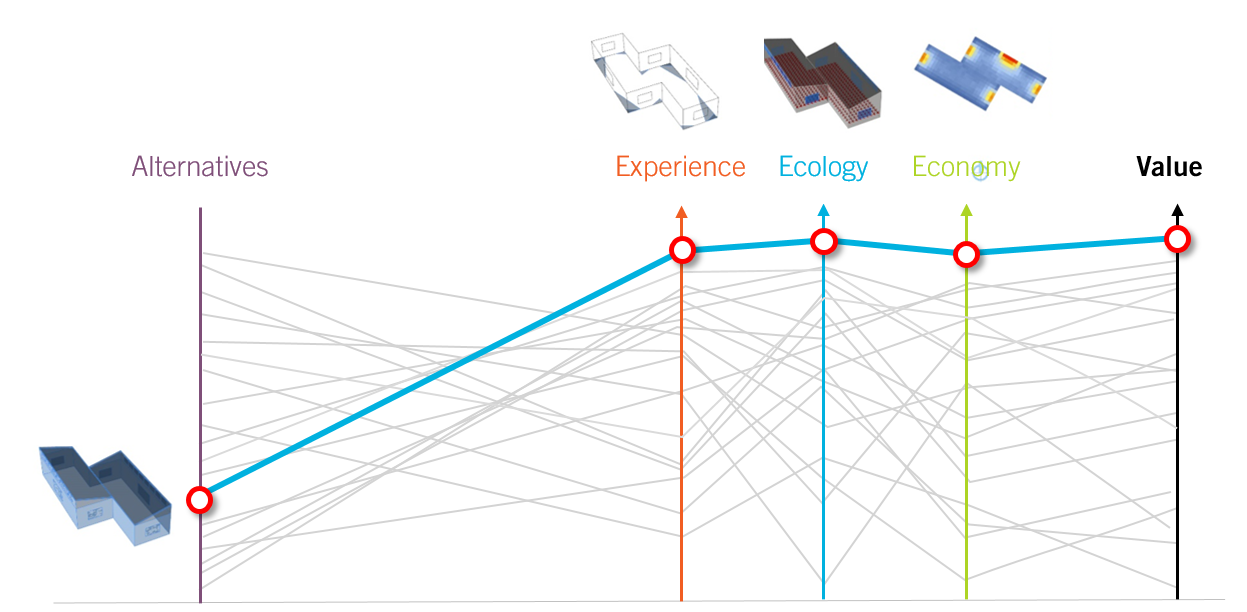

Design Space Construction:

Defining, optimizing, and communicating performance-based building design spaces

Workshop Leaders:

John Haymaker (Perkins+Will)

Marcelo Bernal (Perkins+Will, UTF Santa María)

Victor Okhoya (Perkins+Will)

Roya Rezaee (Perkins+Will)

Omer Cavusoglu (Perkins+Will)

Mohammad Asl (Autodesk)

Today’s building design challenges require multidisciplinary teams to systematically define and search through design spaces, understand and optimize tradeoffs, and make and communicate transparent, performance-based decisions. In this session, participants will learn a methodology and associated tools for formulating, executing, and reporting the performance of their design spaces. They will learn to:

• Formulate a design space, including Objectives, Alternatives, Impacts, and Value.

• Create a generative model exploring building form and materials.

• Define and implement experimental, environmental, and economic analyses.

• Explore a design space, including understanding importance and sensitivity of design parameters.

• Define a value equation, and optimize the building design.

• Report the results into an online database capable of storing and comparing design spaces.

• Apply these methods to an advanced case study.

- Laptop capable of running the below software with sufficient speed.

- Dynamo or Grasshopper, and select plugins that will be sent to participants before the workshop.

- Intermediate Grasshopper or Dynamo preferred.

- Some experience with Performance analysis, and/or optimization is a plus.

- Computer loaded with Dynamo and/or Grasshopper

WORKSHOP 04

Machine Learning Applications for Design and the Built Environment

Workshop Leaders:

Gwyllim Jahn (RMIT University)

Cameron Newnham (RMIT University)

Applied AI technology and natural language processing is now generating real value in many fields but has seen relatively few creative design or architectural applications. This workshop will demonstrate how to use cloud computing infrastructure to train neural networks on architectural datasets in order to build web-based “design-bots” that assist with common conceptualisation, drawing, mark-up and search based design tasks.The design-bots produced during the workshop will be conceptual prototypes that generate debate around the capacity of AI to disrupt established design industries, processes and workflows. The degree to which bots can exert some influence or agency within design processes may prompt conversations challenging long held beliefs regarding non-human creativity and design authorship. This discourse will be intensified by exhibiting the bots as an interactive exhibition during the conference, extending to a wider audience through their prolonged life as automated bots critiquing design on social media.

Machine / Hardware / Materials:- Desk space and internet connection for all workshop participants.

- Large format HD screen / projector.

- Secured computers / screens for exhibition.

- All workshop activities will take place using free web based tools.

- Rhino3d and Adobe Creative Suite would be beneficial but are not required.

- No prior knowledge is required though some programming experience would be beneficial.

- Laptop running Windows

WORKSHOP 05

Print Fast, Pile High

Workshop Leaders:

Shajay Bhooshan (Zaha Hadid Architects)

Vishu Bhooshan (Zaha Hadid Architects)

Alicia Nahmad (Cardiff University)

David Reeves (Zaha Hadid Architects)

Additional affiliation/support: Block research Group, ETH Zurich

The workshop will be a collaborative design-build exercise which seeks synergies between computational masonry and 3D printing with soft-rigid materials. Participants will be presented with a bespoke Interactive Design Environment (IDE). The IDE enables the synthesis of geometries that are structurally and materially feasible vis-a-vis 3d printing with compression-dominant materials. In addition to the collaborative production of a sizeable prototype, participants will explore the design space offered by this platform through the development of smaller scale physical models.

Machine / Hardware / Materials:- Studio with projector

- Space to assemble prototype (approx 2 x 2 x 2 m)

- 2 industrial robotic arms (1 large and 1 small) with corresponding software (i.e. Robot Studio for ABB robots)

- Clay or other suitable phase changing material (quantity TBD)

- Laser cutter or CNC router

- Tools for assembly (i.e. power drills, drill bits, screwdrivers, masking tape)

- Maya 2016, Rhinoceros 5, Grasshopper

- Beginner level programming experience in C#, Java, or C++.

- A laptop with listed 3d modelling software installed.

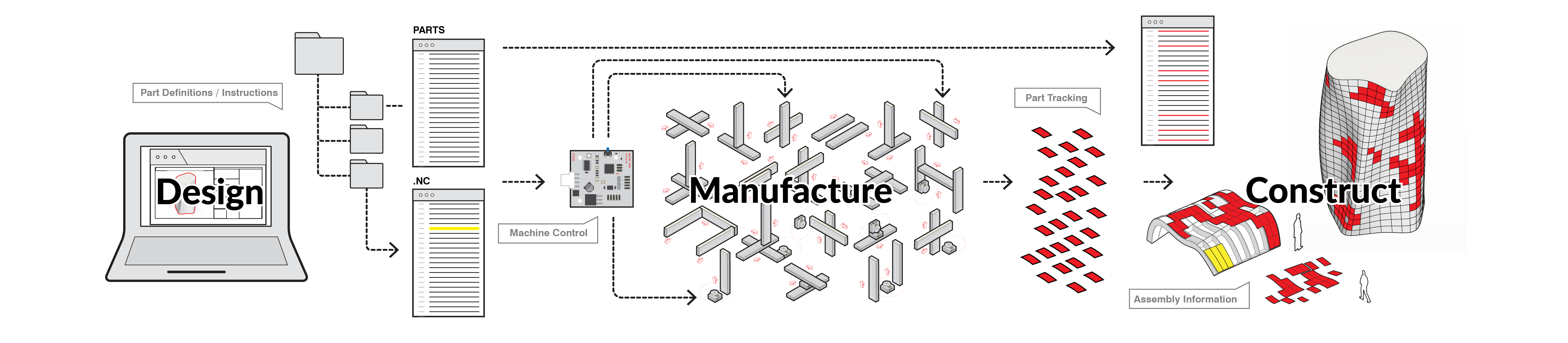

WORKSHOP 06

Pop-Up Production

Workshop Leaders:

James Coleman (A. Zahner Company)

Nadya Peek (University of Washington HCDE/ MIT Center for Bits and Atoms)

Craig Long (Autodesk Dynamo)

This workshop explores the creative possibilities of production automation through machine construction, machine programming, material exploration, and machine control. Part design is only the first step in production. What follows includes geometry rationalization, material optimization, machine programming, motor control, and part management. However, these subsequent steps and the labor that goes into them are often rendered invisible. Different production partners may make vastly different decisions for this invisible work, and those decisions can blow budgets, degrade quality, produce waste, and reduce efficiency. In this workshop we will explicitly explore the tension between design and production by running a machine-based production line.

Participants in this workshop will design and build their fabrication machines using the Cardboard Machine Construction Kit and PyGestalt (networked machine control) with Autodesk Build Space support. Then we will run these machines as a mini-factory to produce 1000s of parts. Depending on the group's design agenda, time, cost, and materials, we will modify and scale our means of production. During the workshop we will physically explore architectural fabrication practices at scale by constructing a full stack design-to-fabrication workflow. This entails:

• Build computational tools to generate designs for 1000s of parts.

• Auto process the fabrication .NC code for each.

• Construct machines that read our fabrication instructions.

• Operate our mini factory of machines to produce the parts.

• Organize and assemble our fabricated parts.

- 3d Printers

- PyGestalt Nodes

- Part materials

- Rhinoceros, Grasshopper, Python, PySerial, PyGestalt

- Experience working Grasshopper, basic scripting knowledge (in Python or otherwise), experience running digital fabrication equipment.

- Their laptop with software preinstalled, any specialty model making tools they can’t live without.